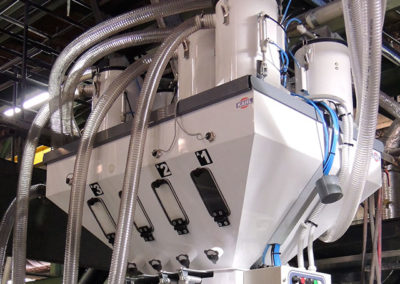

Gravimetric dosifiers description:

Specially design to produce frequent changes in production and to bring a detailed visualization of the different parameters used. Gravimetric dosifiers automatically control the extrusion line from the interface allowing a graphic visualization of all the information and the control of all of its parts in general and of each of them individually.

By means of a fast weighting system it processes in an exact way and in real time the quantity of material consumed in relation to time. The unit is equipped with PLC control and works totally autonomous in case of fail. The equipment has superior automatic fillers with double pneumatic cylinder with relieve valve that ensures sucking. It also counts with filter and self cleaning system. It comes with cylinders and first class brand electrovalves.

KAHL equipments dossify up to 9 materials and have a total control of the process by means of a software. This software automatically controls the speed of tiro and of the screw struders individually or together. The interface, of intuitive use and easy learning, provides numeric and graphic information of the levels of production of each dosifier and of the complete line. It generates alarms, doses, consumption and calibration reports.

Characteristics and functions:

- Production of films of higher quality due to dosifier’s precision.

- Scrap reduction.

- Higher productivity due to fast change of products.

- Reduction of costs owing to savings in raw materials.

- Connection to a second pc in remote access.

- Empty central equipped with regenerative turbine, central control board and sequencer.

- An exact control of extruder’s production through the speed screw, with production capacities from 20 up to 2000 kilograms per hour.